Understanding Surface Coatings

Max Pickus, Environmental Specialist

Surface coatings are a mixture of pigments, solvents, and various additives designed to cover surfaces. Applied by spraying or dipping, these coatings form a thin film when dried or cured, providing a protective or decorative layer on the surface. They are used on a wide range of products, from large items like concrete mixer trucks to smaller hardware components. While surface coatings primarily serve functional purposes, they can also enhance the aesthetic appeal of the coated object.

Why Surface Coatings Require an Air Permit

Surface coatings often contain solvents that include volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and exempt solvents. Key factors such as evaporation rate, boiling point, toxicity, and chemical reactivity of these solvents make it necessary to regulate their use. Due to their potential to harm the environment and human health, an air permit is required to ensure safe and controlled application of surface coatings. Understanding the processes, monitoring emissions, and taking appropriate safety measures are crucial to protect both public health and the surrounding environment.

Photo Source: freepik

Permitting Options for Surface Coating Air Emissions in Texas

In Texas, there are three permitting options from the Texas Commission on Environmental Quality (TCEQ) for regulating surface coating air emissions. The choice of permit depends primarily on two factors: production levels and the location of the operation. Production levels determine the quantity of emissions released, while the location must be sufficiently distanced to minimize impact on neighbors and the surrounding environment.

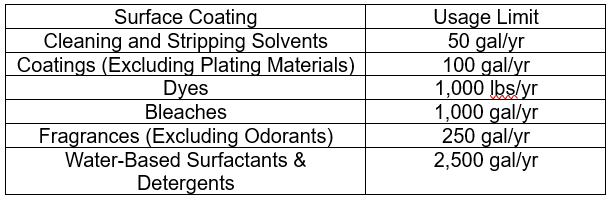

De Minimis

The first permitting option is the De Minimis route for which registration or authorization from TCEQ is not required for certain facilities and sources. If coatings are applied manually by brush, cloth, pad, sponge, dropper, tube dispensing equipment, or spray bottles and pump-up sprayers without any aerosol propellants, then these activities are considered De Minimis. Additionally, a facility can qualify for De Minimis status if its usage levels remain below the specified minimum thresholds listed below.

The usage limits for De Minimis status are:

Permit By Rule 106.433

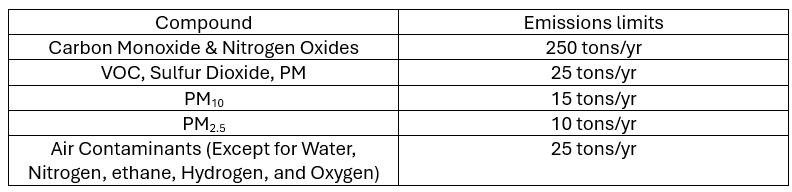

The Permit By Rule (PBR) option is suitable for most applicants. To qualify, facilities must meet two sets of conditions: the general PBR conditions applicable to all PBRs, and the specific requirements outlined in 30 Texas Administrative Code §106.433 for Surface Coating Operations.

PBR 106.4 General Conditions

PBR 106.433: Indoor vs. Outdoor Surface Coating Operations

Under Permit By Rule 106.433, there are two primary options for surface coating operations: outdoor/unenclosed and indoor/booth/enclosed. Both are subject to the same emissions limits, but the choice between them depends on factors like cost and location.

For outdoor operations, no filter system is required, making it a cost-effective option if adequate space is available. However, the operation must be at least 50 feet from the nearest property line and 250 feet from the nearest off-property structure, such as a residence, office building, or recreational area.

The indoor/booth/enclosed option may have higher costs due to the need for a water wash or dry filter system to control emissions. However, it offers more flexibility in location, as there are no distance limitations, making it a suitable choice for smaller or more confined spaces if budget allows.

New Source Review (NSR) Permit

If your operation doesn't meet the requirements of PBR 106.433, the New Source Review (NSR) Permit is the next step. This option allows you to create a custom permit tailored to your specific needs, whether you're exceeding emission limits or distance restrictions. However, the NSR process is more detailed, costly, and time-consuming, requiring computerized Air Dispersion Modeling to ensure your operation complies with environmental standards. The goal is to demonstrate that the operation's impact on the environment will be negligible at and beyond the property line. While this route offers the most flexibility, it must be proven that the operation will not have a negative environmental impact.

In summary, selecting the appropriate permitting option for surface coating operations in Texas requires careful consideration of production levels, location, and environmental impact. Whether opting for the streamlined De Minimis status, the more common Permit By Rule 106.433, or the flexible but complex New Source Review Permit, each pathway ensures that surface coating activities are conducted safely and responsibly, protecting both the environment and public health. Understanding and complying with these regulations is essential for a successful and sustainable operation. For guidance on your next project, contact Westward for a consultation.